An Led Tri-proof Light Factory is where industrial lighting solutions begin. At cigelighting, every tri-proof fixture goes through a detailed process that combines purposeful design, stable engineering, and structured production. This article offers a look into that process and what buyers can expect when working with a factory like cigelighting.

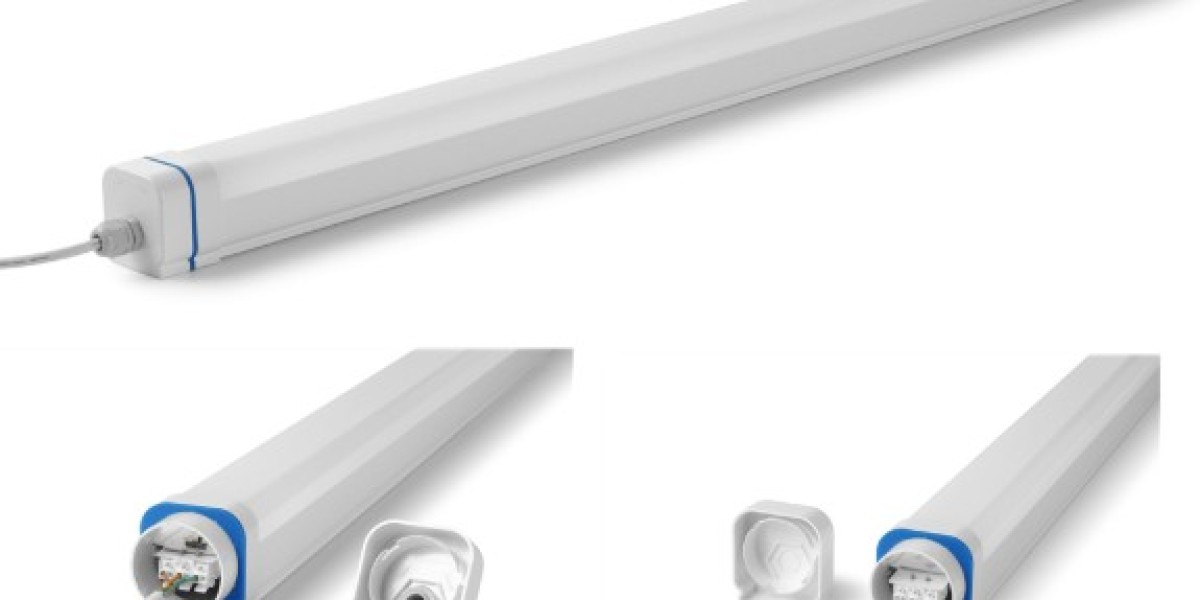

Each product at the cigelighting factory starts with a functional design focused on resisting dust, moisture, and impact. Engineers create detailed plans based on use environments like warehouses, transit hubs, or tunnels. After the design stage, sourcing begins. Materials such as aluminum housings, polycarbonate diffusers, and waterproof connectors are selected to meet safety and durability expectations.

Assembly at the cigelighting factory follows an efficient line process. Fixtures are built with care, then checked for key characteristics such as seal integrity, light uniformity, and thermal performance. Testing happens at every step—not just at the end—so every unit meets the required working conditions before it leaves the facility.

Unlike mass production that overlooks variation, cigelighting offers customization for clients needing specific lengths, installation styles, or wattages. This flexibility makes it easier for project managers to find the right fit without redesigning spaces around the lighting.

Inside a professional LED Tri-proof Light Factory like cigelighting, precision and function guide every step. Explore their lighting solutions and learn more about their capabilities at https://www.cigelighting.com/